The unloading of products or goods corresponds to the unloading of chemical products or goods from the truck in order to store them in dedicated storage areas. To guarantee the preservation of these products, it is essential to use the right equipment.

Before you invest, it’s a good idea to find out about the different types of containers you can use, such as cabinets, stations and depots. Stockage & Systèmes offers models that can be customized to suit your needs.

Each installation has its own solution

Stockage & Systèmes, the manufacturer of boxes, cabinets and unloading stations referenced throughout the industry

Stockage & Systèmes creates, designs, manufactures and supplies equipment to protect your operators and secure your facilities. All SECURIBOX’Optima® and SECURIBOX’Classic® boxes, stations and depot cabinets enable you to comply with ISO 14000 regulations and standards.

You get a complete solution that keeps you informed about the unloading process and protects you from risks.

With SECURIBOX’Optima® and SECURIBOX’Classic®, you can safely remove chemicals without the need for an intermediate pump. We also take care to protect the environment by simplifying drip collection and pipe emptying. An effective leak detection system is also in place.

Order enclosures, stations and depot cabinets customized to the specific features of your business and the region in which you operate. All the products we deliver are immediately ready for use, complete with technical file, commissioning manual and hydraulic test certificates.

We offer a complete range of products to facilitate the handling, storage and conservation of chemical products. We work hard to ensure the safety of operations and operators, to reduce the risk of errors, splashes, dosing equipment malfunctions or pipe disconnections when pressurized.

SECURIBOX'Optima®: unloading upwards by pressurizing the tank

The all-in-one solution: signal, protect, recover, rinse.

With SECURIBOX’Optima®, Stockage & Systèmes continues to innovate in the safety of chemical product unloading without an intermediate pump.

SECURIBOX’Optima® is specifically designed for venting to tanks with vertical piping, with a “high-security sampling” system, in a box or terminal version. A wide choice of colors is available to distinguish your stored products.

SECURIBOX'Optima® wall box - wall or stand mounting

- – UV-resistant HDPE

- – Padlockable manual valve

- – Half fireman’s fitting + plug (EPDM gasket) + chain

- – 40-litre drip tray

- – HDPE valve mounting plate

- – Padlockable door with ergonomic handle

- – Sample canister

- – PPE box + PPE (acid-proof suit + gloves + goggles)

- – PVC DN20 cabinet drain valve, EPDM seal

- – Safety markings

- – Product identification plate

- – Visual float level

- – 2 tapped 2″ drain ports (right or left)

- – 4 holes for floor mounting

- – Safety markings

- – DN15 valve for draining the discharge column

Options :

- – 3-function ALARM kit (RED flashing light, GREEN flashing light, electronic siren) to provide information on levels reached in the tank

- – FPM (Viton) seals on discharge and drain valves

- – Limit switch box + 2 24V contacts on unloading valve

- – Vertical float-type leak detector, NO or NC, breaking capacity 250V/1A/50W/0VA

- – Customer logo engraving

- – Other hood colors (black, gray, light gray, dark blue, light blue, green, light green, yellow, orange, red)

SECURIBOX Optima® self-stabilizing bollard - Floor fixing

- – UV-resistant HDPE

- – Padlockable manual valve DN50 or DN80, EPDM seal

- – Half fireman’s fitting + plug (EPDM gasket) + chain

- – Drip tray 150 liters

- – HDPE valve mounting plate

- – Padlockable door with ergonomic handle

- – Sample canister

- – PPE box + PPE (acid-proof suit + gloves + goggles)

- – PVC DN20 cabinet drain valve, EPDM seal

- – Safety markings

- – Product identification plate

- – Visual float level

- – 2 tapped 2″ drain ports (right or left)

- – 4 holes for floor mounting

- – Safety markings

- – DN15 valve for draining the discharge column

Options :

- – 3-function ALARM kit (RED flashing light, GREEN flashing light, electronic siren) to provide information on levels reached in the tank

- – FPM (Viton) seals on discharge and drain valves

- – Limit switch box + 2 24V contacts on unloading valve

- – Vertical float-type leak detector, NO or NC, breaking capacity 250V/1A/50W/0VA

- – Customer logo engraving

- – Other hood colors (black, gray, light gray, dark blue, light blue, green, light green, yellow, orange, red)

WALL BOX SECURIBOX' OPTIMA : WALL FIXING - VERTICAL VALVE | Add New | Add New | Add New | Add New |

Valve nominal diameter (mm) | Half fireman’s fitting diameter (Guillemin) | Piping and vavles material | Seal material | References |

DN50 - 2'' | 2'' | PVC-U | EPDM | SECO-C502-UE |

DN50 - 2'' | 2'' | PVC-U | FKM (VITON) | SECO-C502-UV |

DN50 - 2'' | 2'' | INOX 304L | EPDM | SECO-C502-SE |

DN50 - 2'' | 2'' | INOX 304L | FKM (VITON) | SECO-C502-SV |

DN80 - 3'' | 3'' | PVC-U | EPDM | SECO-C803-UE |

DN80 - 3'' | 3'' | PVC-U | FKM (VITON) | SECO-C803-UV |

DN80 - 3'' | 3'' | INOX 304L | EPDM | SECO-C803-SE |

DN80 - 3'' | 3'' | INOX 304L | FKM (VITON) | SECO-C803-SV |

DN100 - 4'' | 4'' | PVC-U | EPDM | SECO-C99-UE |

DN100 - 4'' | 4'' | PVC-U | FKM (VITON) | SECO-C99-UV |

DN100 - 4'' | 4'' | INOX 304L | EPDM | SECO-C99-SE |

DN100 - 4'' | 4'' | INOX 304L | FKM (VITON) | SECO-C99-SV |

SELF-STABILIZING BOLLARD SECURIBOX' OPTIMA : FLOOR FIXING - VERTICAL VALVE | Diamètre raccord pompier (Guillemin) | Matière tuyauterie et vanne | Add New | Add New |

Valve nominal diameter (mm) | Half fireman’s fitting diameter (Guillemin) | Piping and vavles material | Seal material | References |

DN50 - 2'' | 2'' | PVC-U | EPDM | SECO-B502-UE |

DN50 - 2'' | 2'' | PVC-U | FKM (VITON) | SECO-B502-UV |

DN50 - 2'' | 2'' | INOX 304L | EPDM | SECO-B502-SE |

DN50 - 2'' | 2'' | INOX 304L | FKM (VITON) | SECO-B502-SV |

DN80 - 3'' | 3'' | PVC-U | EPDM | SECO-B803-UE |

DN80 - 3'' | 3'' | PVC-U | FKM (VITON) | SECO-B803-UV |

DN80 - 3'' | 3'' | INOX 304L | EPDM | SECO-B803-SE |

DN80 - 3'' | 3'' | INOX 304L | FKM (VITON) | SECO-B803-SV |

DN100 - 4'' | 4'' | PVC-U | EPDM | SECO-B99-UE |

DN100 - 4'' | 4'' | PVC-U | FKM (VITON) | SECO-B99-UV |

DN100 - 4'' | 4'' | INOX 304L | EPDM | SECO-B99-SE |

DN100 - 4'' | 4'' | INOX 304L | FKM (VITON) | SECO-B99-SV |

SECURIBOX'Classic® : gravity discharge downwards or pressurization of the tank

SECURIBOX’Classic® are pressurized tank decanting solutions designed for companies handling chemicals, who want to guarantee the safety of their employees and the environment, while simplifying their decanting operations. this range is recommended for vertical valve discharge with rising pipes.

There are three SECURIBOX’Classic® models, each designed to meet different needs.

The SECURIBOX’Classic® cabinet is a wall-mounted or stand-mounted solution that can be used for unloading by pressurizing the truck. It includes a horizontal valve to pressurize the tank. It features a 30-liter drip tray and standard recommendations engraved into the body.

The SECURIBOX’Classic® bollard is a decanting solution that can be used for pump, compressed air or gravity decanting. It includes a valve and a DN50 or DN80 discharge connection and a 300-liter drip tray. It is self-standing and can be fixed to the floor. Our SECURIBOX ranges are designed for use within the limits of -30°C and +50°C.

It also features an integrated PPE box and standard recommendations engraved into the body. The SECURIBOX’Classic® bollard is also available in the SSECURIBOX’Classic® “canister” version, with drips collected in a canister (not supplied) instead of a tank. By choosing SECURIBOX’Classic®, companies can benefit from safe, efficient unloading while complying with safety and environmental regulations.

SECURIBOX'Classic® wall box - wall or stand mounting

- – Valve and discharge connection in DN50 or DN80

- – Pump, compressed-air or gravity discharge

- – Drip tray in cabinet (30l)

- – Wall or bracket mounting

- – Integrated PPE box

- – Standard recommendations set in stone

- – Dimensions W700 x D750 x H1100mm

- – Weight 20kg

Options :

- – 3-function ALARM kit (RED flashing light, GREEN flashing light, electronic siren) to provide information on levels reached in the tank

- – FPM (Viton) seals on discharge and drain valves

- – Limit switch box + 2 24V contacts on unloading valve

- – Vertical float-type leak detector, NO or NC, breaking capacity 250V/1A/50W/0VA

- – Customer logo engraving

- – Other hood colors (black, gray, light gray, dark blue, light blue, green, light green, yellow, orange, red)

SECURIBOX'Classic® 300 liter tank terminal - self-stabilizing - floor fixing

- – 50C or 80C (version with tank)

- – Valve and discharge connection in DN50 or DN80

- – Pump, compressed air or gravity discharge

- – Drainage recovery (300l)

- – Floor-mounted – Self-stabilizing

- – Integrated PPE box

- – Standard recommendations set in stone

- – Dimensions W850 x D850 x H1800mm

- – Weight 40kg

Options :

- – 3-function ALARM kit (RED flashing light, GREEN flashing light, electronic siren) to provide information on levels reached in the tank

- – FPM (Viton) seals on discharge and drain valves

- – Limit switch box + 2 24V contacts on unloading valve

- – Vertical float-type leak detector, NO or NC, breaking capacity 250V/1A/50W/0VA

- – Customer logo engraving

- – Other hood colors (black, gray, light gray, dark blue, light blue, green, light green, yellow, orange, red)

SECURIBOX'Classic® tank bollard - self-stabilizing - ground fixing

- – Valve and discharge connection in DN50 or DN80

- – Pump, compressed-air or gravity discharge

- – Padlockable transparent door for access to canister compartment (not supplied)

- – Drips collected in canister (not supplied)

- – Floor-mounted – Self-stabilizing

- – Integrated PPE box

- – Embedded standard recommendations

- – Dimensions W850 x D850 x H1800mm

- – Weight 40kg

- Options :

- – 3-function ALARM kit (RED flashing light, GREEN flashing light, electronic siren) to provide information on levels reached in the tank

- – FPM (Viton) seals on discharge and drain valves

- – Limit switch box + 2 24V contacts on unloading valve

- – Vertical float-type leak detector, NO or NC, breaking capacity 250V/1A/50W/0VA

- – Customer logo engraving

- – Other hood colors (black, gray, light gray, dark blue, light blue, green, light green, yellow, orange, red)

WALL BOX SECURIBOX' CLASSIC : - WALL FIXING - HORIZONTAL VALVE | Add New | Add New | Add New | Add New |

Valve nominal diameter (mm) | Half fireman’s fitting diameter (Guillemin) | Piping and vavles material | Seal material | References |

DN50 - 2'' | 2'' | PVC-U | EPDM | SECUC-502UEB |

DN50 - 2'' | 2'' | PVC-U | FKM (VITON) | SECUC-502UVB |

DN50 - 2'' | 2'' | INOX 304L | EPDM | SECUC-502SEB |

DN50 - 2'' | 2'' | INOX 304L | FKM (VITON) | SECUC-502SVB |

DN80 - 3'' | 3'' | PVC-U | EPDM | SECUC-803UEB |

DN80 - 3'' | 3'' | PVC-U | FKM (VITON) | SECUC-803UVB |

DN80 - 3'' | 3'' | INOX 304L | EPDM | SECUC-803SEB |

DN80 - 3'' | 3'' | INOX 304L | FKM (VITON) | SECUC-803SVB |

SECURIBOX' CLASSIC : SELF-STABILIZING BOLLARD WITH TANK TERMINAL FLOOR FIXING - HORIZONTAL VALVE | Add New | Add New | Add New | Add New |

Valve nominal diameter (mm) | Half fireman’s fitting diameter (Guillemin) | Piping and vavles material | Seal material | References |

DN50 - 2'' | 2'' | PVC-U | EPDM | SECUB-502UEC |

DN50 - 2'' | 2'' | PVC-U | FKM (VITON) | SECUB-502UVC |

DN50 - 2'' | 2'' | INOX 304L | EPDM | SECUB-502SEC |

DN50 - 2'' | 2'' | INOX 304L | FKM (VITON) | SECUB-502SVC |

DN80 - 3'' | 3'' | PVC-U | EPDM | SECUB-803UEC |

DN80 - 3'' | 3'' | PVC-U | FKM (VITON) | SECUB-803UVC |

DN80 - 3'' | 3'' | INOX 304L | EPDM | SECUB-803SEC |

DN80 - 3'' | 3'' | INOX 304L | FKM (VITON) | SECUB-803SVC |

SECURIBOX' CLASSIC : SELF-STABILIZING BOLLARD WITH CANISTER COMPARTMENT* | Add New | Add New | Add New | Add New |

Valve nominal diameter (mm) | Half fireman’s fitting diameter (Guillemin) | Piping and vavles material | Seal material | References |

DN50 - 2'' | 2'' | PVC-U | EPDM | SECUB-502UEB |

DN50 - 2'' | 2'' | PVC-U | FKM (VITON) | SECUB-502UVB |

DN50 - 2'' | 2'' | INOX 304L | EPDM | SECUB-502SEB |

DN50 - 2'' | 2'' | INOX 304L | FKM (VITON) | SECUB-502SVB |

DN80 - 3'' | 3'' | PVC-U | EPDM | SECUB-803UEB |

DN80 - 3'' | 3'' | PVC-U | FKM (VITON) | SECUB-803UVB |

DN80 - 3'' | 3'' | INOX 304L | EPDM | SECUB-803SEB |

DN80 - 3'' | 3'' | INOX 304L | FKM (VITON) | SECUB-803SVB |

Canister not provided*

* Cylinder not included

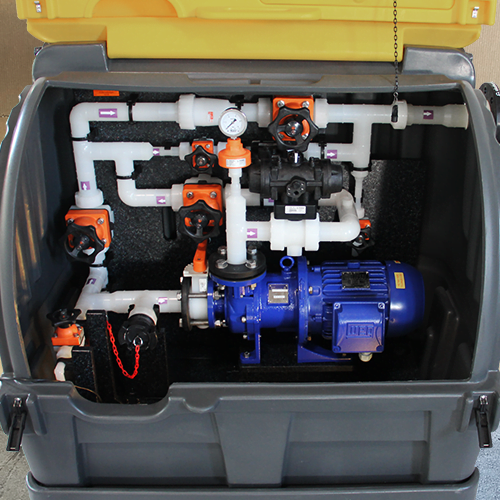

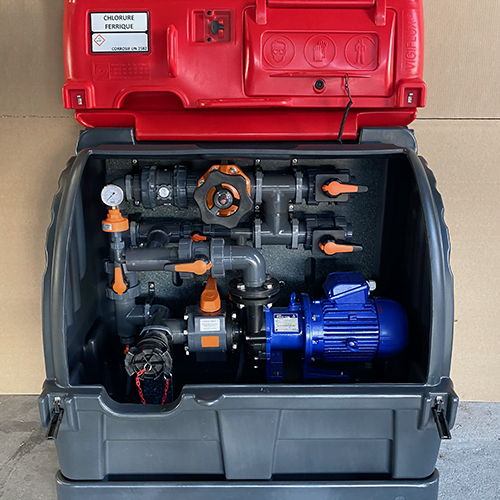

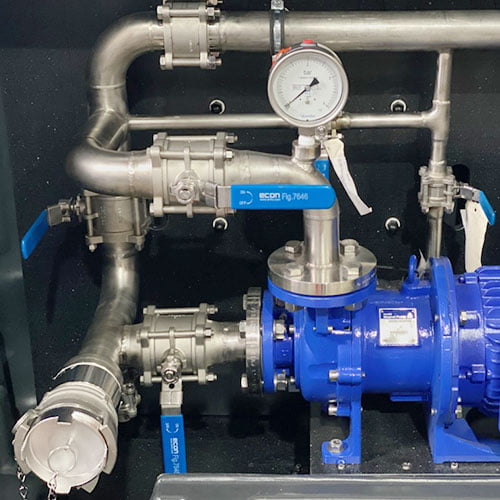

VIGIFLUX® E and P Series - with integrated “plug & play »

up to 30 m3/h

VIGIFLUX® is the ideal solution for the safe transfer of hazardous materials. This recyclable HDPE (High Density Polyethylene) box is fitted with a customized diaphragm or centrifugal pump and piping, reducing toxic fumes and product leaks during chemical transfer from one container to another. At Stockage & Systèmes, we understand the importance of minimizing exposure to hazardous materials during transport and handling, which is why we developed the VIGIFLUX®.

The VIGIFLUX® cabinet can accommodate air-operated diaphragm pumps or magnetic drive centrifugal pumps, with flow rates up to 35 m3/h. This pumping system can be calibrated to pump the right amount for each application, offering a customized solution for your chemical transfer needs.

VIGIFLUX® E Series with integrated “plug & play” electric pump

- HDPE support bin :

- – Ergonomic main bin with drip tray drips (200 liters)

- – Padlockable hinged cover with porthole

- – Integrated molded vane

- – PPE box + 1 set of PPE

- – Total draining by manual valve

- Process :

- – Centrifugal pump 5 m3/h, 30 m3/h or 50 m3/h

- – Safety devices and process equipment

- – Piping, process and drain valves

- – Fireman’s coupling for truck hose connection

- Options :

- – Automatic valves with limit switches

- – Flow measurement

- – Pump dry-running protection

- – Vertical float-type leak detector, NO or NC, breaking capacity 250V/1A/50W/0VA

- – Forced-air heater 400-475W / 230VAC (Risk of freezing)

- – 3-function ALARM kit (RED and GREEN flashing lights, siren) to provide information on pump malfunctions, liquid in the tank, tank levels reached, etc.

- – Wheeled stand for “mobile” version

- – Electrical junction box

- – Customer logo engraving

- – Other hood colors (black, gray, light gray, dark blue, light blue, green, light green, yellow, orange, red)

VIGIFLUX® P Series with integrated “plug & play” pneumatic pump

- HDPE support tray :

- – Ergonomic main bin with drip tray drips (200 liters)

- – Padlockable hinged cover with porthole

- – Integrated molded vane

- – PPE box + 1 set of PPE

- – Total draining via manual valve

- Process :

- – Centrifugal pump 5 m3/h, 30 m3/h or 50 m3/h

- – Safety devices and process equipment

- – Piping, process and drain valves

- – Fireman’s coupling for truck hose connection

- Options :

- – Automatic valves with limit switches

- – Flow measurement

- – Pump dry-running protection

- – Vertical float-type leak detector, NO or NC, breaking capacity 250V/1A/50W/0VA

- – Forced-air heater 400-475W / 230VAC (Risk of freezing)

- – 3-function ALARM kit (RED and GREEN flashing lights, siren) to provide information on pump malfunctions, liquid in the tank, tank levels reached, etc.

- – Wheeled stand for “mobile” version

- – Electrical junction box

- – Customer logo engraving

- – Other hood colors (black, gray, light gray, dark blue, light blue, green, light green, yellow, orange, red)

Thanks to the VIGIFLUX® cabinet, the safety of your chemical installations is enhanced during the unloading process. What’s more, this system reduces the risk of “water hammer”, which occurs during tank pressurization.

The VIGIFLUX® box is designed with a high-density polyethylene structure, impervious to corrosion, and can hold up to 150 liters thanks to its drip tray. It can also be fitted with wheels for greater mobility. The size of this box is standardized, with overall dimensions of 1200 mm in length, 800 mm in width and 1230 mm in height when the cover is closed.

As an option, VIGIFLUX® can be fitted with a communicating leak detector to reduce air pollution and the risk of toxic vapors, a heating device to prevent freezing in extreme situations, and an alarm that monitors the liquid level in the tank and whether the system is running dry.

With VIGIFLUX® , you can be sure of a safe and secure transfer of chemicals, while minimizing risks to health and the environment.

The “Plug & Play” integrated pump is a pump built into a piping system that can be connected easily and immediately without the need for additional configuration. Plug & Play” means plug in and play, which means installation is quick and easy. This feature is very useful for equipment requiring fast and efficient start-up, without the need for complicated adjustments. The integrated “Plug & Play” pump saves time and increases efficiency.

UNLOADING STATIONS WITH INTEGRATE ELECTRIC PUMP VIGIFLUX SERIE-E (unloading for 1 or 2 tanks) | Add New | Add New | Add New | Add New | Add New | Add New | Add New |

For pump flow (to be confirmed for each case)* | Piping valves, accessories, connections material | Seal material | Valve diameter at inlet pump | Valve diameter at oulet pump | Half fireman’s fitting diameter for tanker connection : | Quantity of unloading lines (Tank to fill) | References |

5 to 15 m3 * | PVC-U | EPDM | DN50 2'' | DN50 2'' | 2'' | 1 | VIUE50502-1 |

5 to 15 m3 * | PVC-U | FKM (VITON) | Add New | Add New | Add New | Add New | VIUV50502-1 |

5 to 15 m3 * | PVDF | EPDM | Add New | Add New | Add New | Add New | VIFE50502-1 |

5 to 15 m3 * | PVDF | FKM (VITON) | Add New | Add New | Add New | Add New | VIFV50502-1 |

5 to 15 m3 * | INOX 304L | EPDM | Add New | Add New | Add New | Add New | VISE50502-1 |

5 to 15 m3 * | INOX 304L | FKM (VITON) | Add New | Add New | Add New | Add New | VISV50502-1 |

5 to 15 m3 * | PVC-U | EPDM | Add New | Add New | 3'' | Add New Add New Add New Add New Add New Add New | VIUE50503-1 |

5 to 15 m3 * | PVC-U | FKM (VITON) | Add New | Add New | Add New | Add New | VIUV50503-1 |

5 to 15 m3 * | PVDF | EPDM | Add New | Add New | Add New | Add New | VIFE50503-1 |

5 to 15 m3 * | PVDF | FKM (VITON) | Add New | Add New | Add New | Add New | VIFV50503-1 |

5 to 15 m3 * | INOX 304L | EPDM | Add New | Add New | Add New | Add New | VISE50503-1 |

5 to15 m3 * | INOX 304L | FKM (VITON) | Add New | Add New | Add New | Add New | VISV50503-1 |

15 to 25 m3 * | PVC-U | EPDM | DN65 2'' 1/2 | DN50 2'' | 3'' | Add New | VIUE65503-1 |

15 to 25 m3 * | PVC-U | FKM (VITON) | Add New | Add New | Add New | Add New | VIUV65503-1 |

15 to 25 m3 * | PVDF | EPDM | Add New | Add New | Add New | Add New Add New | VIFE65503-1 |

15 to 25 m3 * | PVDF | FKM (VITON) | Add New | Add New | Add New | Add New Add New | VIFV65503-2 |

15 to 25 m3 * | INOX 304L | EPDM | Add New | Add New | Add New | Add New Add New | VISE65503-2 |

15 to 25 m3 * | INOX 304L | VITON | Add New | Add New | Add New | Add New Add New | VISV65503-2 |

Add New | Add New | Add New | Add New | Add New | Add New | Add New | |

5 to 15 m3 * | PVC-U | EPDM | DN50 2'' | DN50 2'' | 2'' | 2 | VIUE50502-2 |

5 to 15 m3 * | PVC-U | FKM (VITON) | Add New | Add New | Add New | Add New | VIUV50502-2 |

5 to 15 m3 * | PVDF | EPDM | Add New | Add New | Add New | Add New | VIFE50502-2 |

5 to 15 m3 * | PVDF | FKM (VITON) | Add New | Add New | Add New | Add New | VIFV50502-2 |

5 to 15 m3 * | INOX 304L | EPDM | Add New | Add New | Add New | Add New | VISE50502-2 |

5 to 15 m3 * | INOX 304L | FKM (VITON) | Add New | Add New | Add New | Add New | VISV50502-2 |

15 to 25 m3 * | PVC-U | EPDM | DN65 2'' 1/2 | DN50 2'' | 3'' | Add New | VIUE65503-2 |

15 to 25 m3 * | PVC-U | FKM (VITON) | Add New | Add New | Add New | Add New | VIUV65503-2 |

15 to 25 m3 * | PVDF | EPDM | Add New Add New Add New Add New Add New Add New | Add New | Add New | Add New | VIFE65503-2 |

15 to 25 m3 * | PVDF | FKM (VITON) | Add New | Add New | Add New | Add New | VIFV65503-2 |

15 to 25 m3 * | INOX 304L | EPDM | Add New | Add New | Add New | Add New | VISE65503-2 |

15 to 25 m3 * | INOX 304L | FKM (VITON) | Add New | Add New | Add New | Add New | VISV65503-2 |

VIGIFLUX® L Series, to fill up to 4 tanks in a single unloading point

VIGIFLUX® L-Series

- HDPE support tray :

- – Ergonomic main bin with drip tray drips (200 liters)

- – Padlockable hinged cover with porthole

- – Integrated molded vane

- – PPE box + 1 set of PPE

- – Total draining by manual valve

- Process :

- – Safety devices and process equipment

- – Piping, process and drain valves

- – Up to 4 outputs possible

- – Fireman’s coupling for truck hose connection

- Options :

- – Automatic valves with limit switches

- – Flow measurement

- – Vertical float-type leak detector, NO or NC, breaking capacity 250V/1A/50W/0VA

- – Forced-air heater 400-475W / 230VAC (Risk of freezing)

- – 3-function ALARM kit (RED and GREEN flashing lights, siren) to provide information on pump malfunctions, liquid in the tank, tank levels reached, etc.

- – Wheeled stand for “mobile” version

- – Electrical junction box

- – Customer logo engraving

- – Other hood colors (black, gray, light gray, dark blue, light blue, green, light green, yellow, orange, red)

This version of the VIGIFLUX® has the same features as the VIGIFLUX® with integrated “plug & play” pump, it reinforces the safety of your chemical installations and reduces the risk of “water hammer” thanks to its robustness.

This is a non-pump version, with unloading performed by pressurizing the tank or using an intermediate pump. Choose this box if you’re looking for a pump-free, mobile, safe and durable unloading system.

Why choose our unloading ranges ?

- Superior quality: our products are designed with high-quality materials to ensure maximum durability and reliability.

2. Increased safety: our unloading cabinets are designed to protect operators, installations and the environment from the hazards inherent in unloading chemicals.

3. Regulatory compliance: our products comply with current regulations and standards to ensure safe, environmentally-friendly use.

4. Innovative technology: we use the latest technologies to offer superior chemical decanting solutions.

5. Adaptability: our products are available in several sizes and can be adapted to your specific needs.

6. Technical support: we offer technical support to help you choose and use our products effectively.

1- Essential checks

They must also ensure that the container is still airtight and that the products have not been tampered with. Bulk packages must be unloaded before other types of product. Sorting will make it easier to organize product transport. Sometimes, reconditioning work may be essential. In this case, you need suitable cabinets, stations and depot cabinets.

At the end of each unloading, each customer receives a detailed report on the unloading, so that they can be informed of the arrival of the products ordered on site. Stuffing and unstuffing must be carried out in compliance with clearly defined rules. The expertise of qualified technicians is essential: the means of transport and the containers must be adapted to guarantee the stability of the products and the correct balancing of the masses until arrival.

2- Specific techniques for successfully unloading products

All the necessary safety equipment, such as fire extinguishers, safety showers as required by the regulations, cabinets, filling stations and cabinets, must be in place to avoid any risks associated with the handling and storage of chemical products. Managers must apply the most appropriate unloading techniques. They can carry out gravity unloading if products are transferred to tanks located below the unloading point. The complementary use of forced air can be considered to accelerate product transfer.

Pressurized unloading is also possible when chemicals are transported in a horizontal tank. The use of a pump to draw in products can also help transfer chemicals at a higher flow rate to cabinets, stations and depots.

The unloading of chemical products is an operation that requires a certain amount of care to ensure the safety of people and property, but also to protect the environment. It is therefore essential to comply with regulations and ISO14000 standards.

Comply with the applicable rules when using unloading boxes, stations and cabinets

The use of dispensing and metering boxes, stations and cabinets facilitates fluid flow measurement and control. This system ensures compliance with safety regulations and environmental standards. This is why containers dedicated to decanting can be fitted with flow meters, level sensors, manual or automatic valves, or pressure regulators. These measurement and control instruments help you comply with current regulations.

Stockage & Systèmes offers you state-of-the-art equipment to facilitate the unloading and storage of your chemical products. All measures are taken to ensure the safety of operations. Thanks to pump unloading, you’re protected from the risks of overflow or explosion that can occur in the event of water hammer when tanks are pressurized.

The boxes, stations and unloading cabinets are made of high-density polyethylene, which is highly resistant to corrosive substances. Whatever your needs, we can offer you customized equipment: single- and double-walled HDPE tanks, palletizable, hooded enclosures and cabinets with drainable drip trays. You can also order fixed or mobile models.

Our entire team is available to discuss your projects

Contact us now!

- +33(0)4 42 12 51 72

- info@stockage-et-systemes.com

- 625 Av. Georges Vacher Z.I 13790 Rousset

What are you looking for?…suggestions