About Stockage & Systèmes

Stockage et Système, 27 years of expertise serving industry. Integrated design and manufacturing.

Stockage & Systèmes for Chemicals

Stockage & Systèmes delivers 300 storage tanks for hazardous liquids every year, in HDPE (high-density polyethylene), PPH (polypropylene), PVC and PVDF.

A source of innovation and ideas, our teams know how to listen to projects and propose innovative solutions that respect our customers’ objectives, respect everyone’s ideas and respect the environment.

Active in the market for over 27 years, Stockage & Systèmes manufactures and delivers storage tanks and turnkey installations in France and Europe for corrosive liquids, concentrated acids, strong bases, chemical effluents, as well as all other food and non-food liquids compatible with HDPE (high-density polyethylene) and PPH (polypropylene).

Stockage & Systèmes is an expert in the choice of materials and their transformation process for the manufacture of storage tanks in polyfused sheets or in MASSIVE ROLLING EXTRUSION, SECURIBOX’CLASSIC and SECURIBOX’OPTIMA decanting boxes, VIGIFLUX decanting stations with integrated pumps up to 30 m3/h, and DOSINGBOX dosing boxes with dosing pumps up to 600 l/h.

Stockage & Systèmes takes charge of projects from start to finish. Whether standard or made-to-measure, our services are based on recognized expertise and perfect technical and technological mastery.

-

Engineering

Design office, Feasibility studies Pre-project, Functional analyses Project costing -

Detail studies

Drawings, 3D modeling

Calculation notes

Manufacturing drawings -

Made in France 🇫🇷

Extrusion solid winding Plastic boilermaking, polyfusion, welding, CNC machining

Rotomolding -

Quality

Experienced skilled welders

Technical files

Materials tracking -

Transport France and abroad

Single consignments and out-of-category consignments

Export partner carriers

Delivery tracking -

Installation

Setting up, craning, handling Assembly, piping, testing

CACES-qualified personnel -

Commissioning

Electricity, Applied automation Start-up assistance for installations

Performance monitoring -

Maintenance Technical checks

Technical support

Solutions

Existing plant inspections

Discover our services and processes

Backed by 3 perfectly mastered manufacturing techniques, Stockage & Systèmes is a manufacturer with a wealth of experience that has enabled our teams to design installations for most industries, manufacture tanks and retention systems for a wide range of situations, and deliver turnkey, tailor-made systems for the biggest names in industry.

We are a manufacturer using the latest techniques in plastics processing:

– Hot extrusion of HDPE and PP granules for the manufacture of tanks by MASSIVE ROLLING EXTRUSION for large volumes, complex liquids and sensitive installations

– Traditional boilermaking using bending and polyfusion of thermoplastic sheets to manufacture single- and double-skin tanks adapted to small volumes and simplified situations.

– Rotomolding for the manufacture of SECURIBOX depot boxes, VIGIFLUX pumping stations and DOSINGBOX and PANEL dosing cabinets.

Our technical department is supported by an integrated Design Office with a perfect command of materials, hydraulics, fluid mechanics, electricity and system automation. As a manufacturer, our prices are always competitive with other players on the market, most of whom offer products that are often imported.

Our raw materials come from first-rate European manufacturers and are checked on arrival.

Every stage of production is subject to quality control. Our control tools are regularly recalibrated to ensure the best results.

Our equipment is packed, dispatched and transported by transport companies specializing in complex shipments, often in exceptional categories. These partner transport companies are selected for the quality of their services.

For projects where installation is carried out by our teams, we rely on national lifting contractors selected for their quality of service and compliance with the safety regulations of each industrial site.

Installation and assembly operations are supervised and carried out by our teams of fitters and pipe fitters, throughout France.

When installation is carried out by our teams, we rely on national lifting contractors selected for their quality of service and compliance with the safety regulations of each industrial site.

Installation and assembly operations are supervised and carried out by our teams of fitters and pipe fitters, or by our partners throughout France and abroad.

Commissioning and technical assistance can be provided by our technical teams. From storage tanks to complete installations, our teams are on hand to provide comprehensive technical support.

We carry out preventive and corrective maintenance on existing installations.

Installations that can be operated safely

Stockage & Systèmes is committed to providing its customers with installations that are safe to operate.

In the design phase, Stockage & Systèmes applies methods that integrate :

– Operation and maintenance operations

– Future working conditions for operators

– Compliance with prevention and safety regulations, thanks to ongoing legal monitoring

– Experience gained from numerous installations already delivered

– Ergonomics for safety and efficiency

For access to tank equipment and the various operating modules, Stockage & Systèmes provides gangways, ladders and access stairs for maintenance and operation operations in complete safety (rigid structures, approved guardrails, non-slip gratings with safety mesh, anti-corrosion protection, etc.).

Stockage & Systèmes expertise:

The only manufacturer of thermoplastic tanks that integrates 2 manufacturing techniques for :

- – Polyfusion plate joining for small-volume single- and double-walled tanks and low-corrosive products

- – EXTRUSION ENROULEMENT MASSIF (by its subsidiary EELIX) for large volumes, for the most complicated acids and bases to store, and for safety with a long service life.

The only manufacturer of patented rotational-molding cabinets and enclosures for :

- – SECURIBOX’CLASSIC® and SECURIBOX’OPTIMA® range depot boxes

- – VIGIFLUX® range of pump dispenser stations

- – DOSINGBOX® and PANEL® dosing cabinets and enclosures

Stockage & Systèmes partner of your facilities

Backed by the experience accumulated by its technicians and engineers through the many systems it has already built, Stockage & Systèmes guarantees customized, high-performance installations. From the pre-project phase through to commissioning, Stockage & Systèmes brings its know-how to bear and creates turnkey installations tailored to each project.

Each project is subject to a number of essential stages:

– Data analysis

– Pre-development: feasibility, cross-effects, evaluations

– Functional analysis

– PID

– Design: project definition, calculations, tests

– Plans, design

– Construction: unloading, storage, regulation, injection

– Electricity, automation

– On-site installation, piping, assembly

– Technical leaflets

– Tests, adjustments, commissioning

– Training

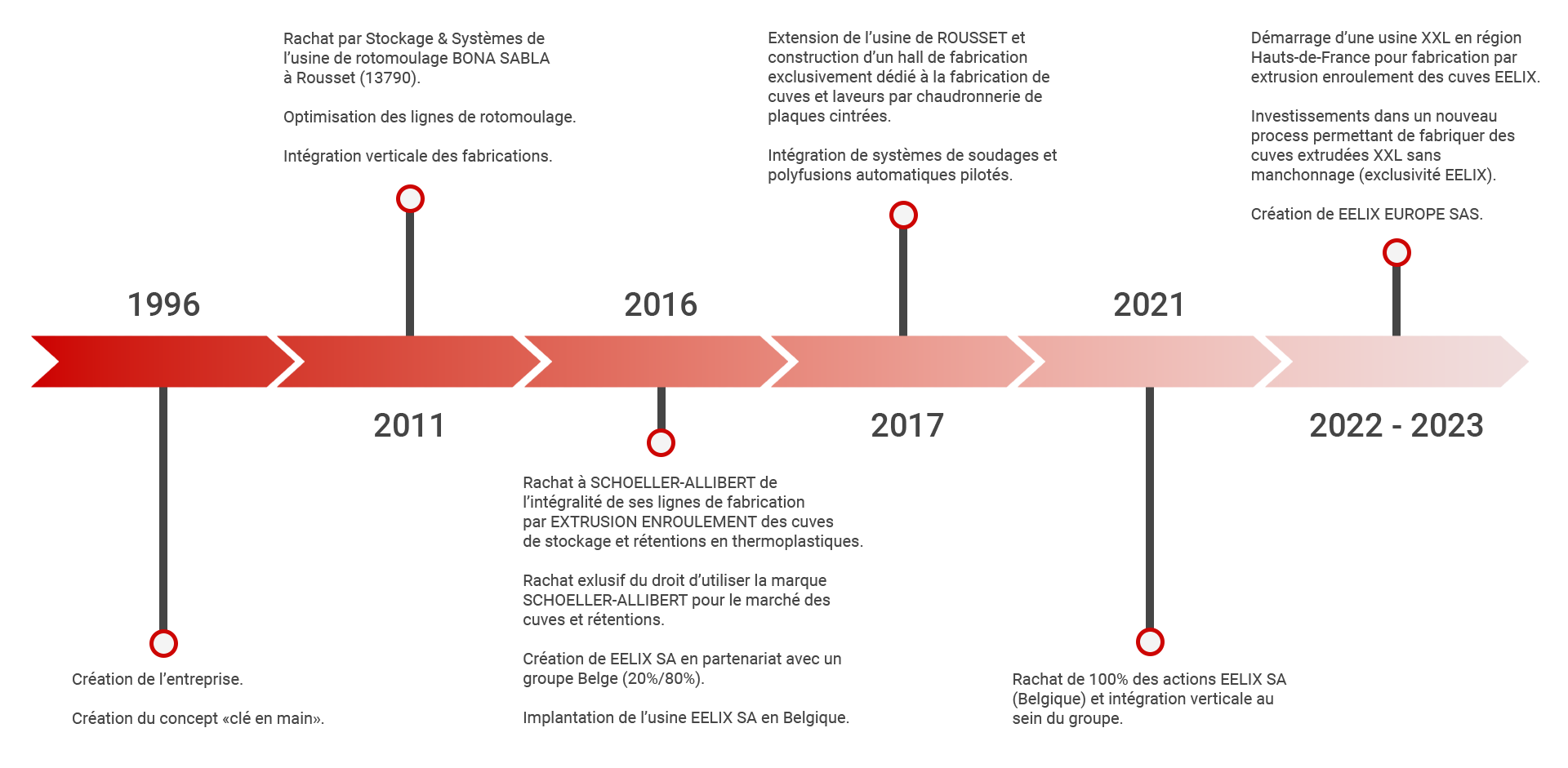

A permanent growth

Our ethical commitment

Our company’s greatest asset is its human capital. The well-being of is fundamental to our overall project to modernize and enhance development. We communicate transparently with our employees and all our customers and partners. Today, legal rules structure the business world. It’s essential for us to respect these laws and regulations to live together better and serve our profession better.

WHAT OUR CUSTOMERS SAY

1 +

Satisfied customers

Derek AuCoin

"I was impressed with the quality of Stockage & Systèmes' storage tanks. Their team was very professional and attentive to my needs, and offered me a personalized storage solution that perfectly met my expectations."

Pierre Lugassy

"Stockage & Systèmes is a very reliable and competent company in the field of chemical storage solutions. Their tanks are of excellent quality and their team is always ready to answer questions and provide useful advice."

Chloé Bolone

"I am very satisfied with the performance of Stockage & Systèmes. Their team was very professional and their storage solution for hazardous liquids was both innovative and environmentally friendly. I recommend this company without hesitation."