Vertical tanks and vats in HDPE (high-density polyethylene) and PP (polypropylene) are ideal for storing and conserving liquids safely and efficiently. If you’re looking for a durable, reliable storage solution for your chemicals, water, food or other liquids, then our tanks are the ideal solution for you.

Our vertical tank and vat ranges are designed to meet your specific storage requirements. Whether you’re looking for a tank for indoor or outdoor use, for small or large quantities of liquids, we have the ideal solution for you. What’s more, our vats and tanks are made from top-quality materials that resist corrosion and deformation, for extended service life.

The advantage of choosing our tanks is that they are custom-made to meet your specific needs. You can customize dimensions and features to suit your storage operations. What’s more, our team of specialists is on hand to help you choose the storage solution best suited to your needs.

Technical sheet

Download our document to see product specific data.

When you choose our tanks, you also benefit from quick and easy installation, thanks to our plug-and-play mounting system. You can be sure that your storage facility will be up and running in no time.

Stockage et Système guarantees you the highest quality in our tanks and reservoirs, ensuring a sound investment. You’ll get a reliable, durable product to meet your long-term storage needs.

Installation of these vertical tanks is quick and easy, making them a popular choice for mobile storage applications. What’s more, they are easy to maintain and can be cleaned without difficulty for optimum long-term performance.

These are reliable, long-lasting solutions for storing chemicals, water, fuel and liquid foodstuffs. With their excellent corrosion resistance and long service life, they are the choice for industrial and commercial applications.

Vertical tanks can be used in a wide range of applications:

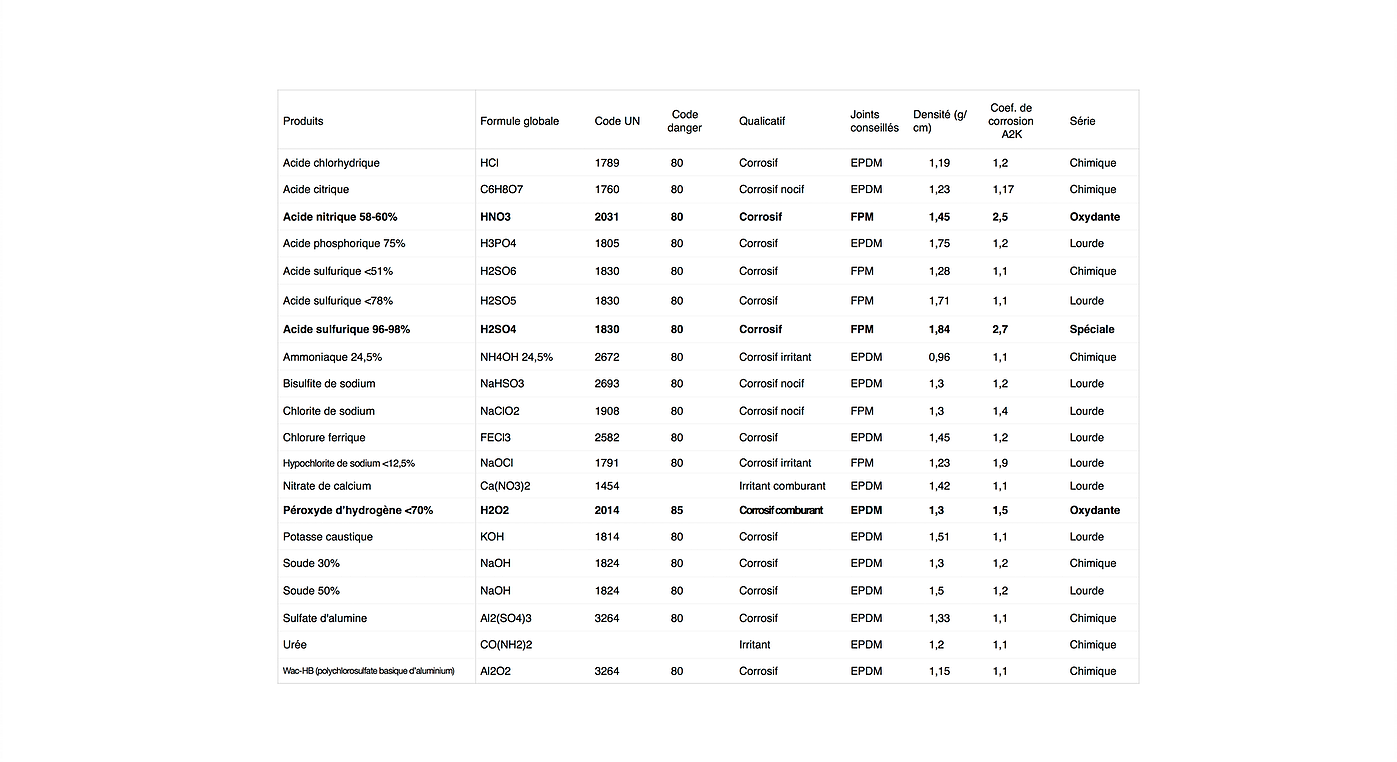

– Chemical industry: acids, bases, corrosives, toxic products

– Food industry: liquid foods, pasta, canned goods

– Pharmaceuticals: liquid medicines, skin care products

– The oil and gas industry: fuels, lubricating oils, petroleum-derived products

– The energy production industry: water, used lubricants, biomass

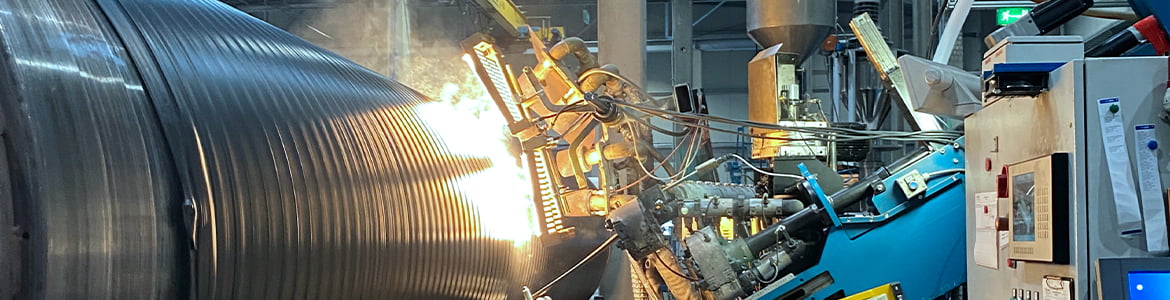

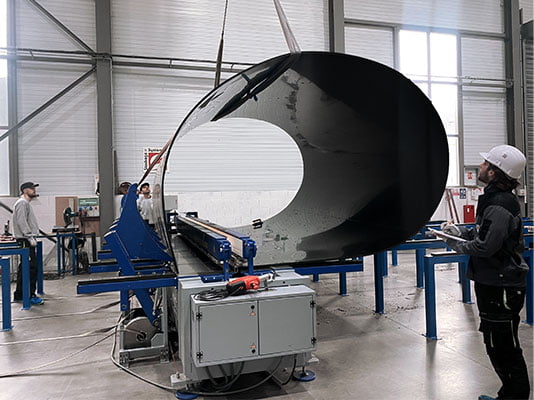

HDPE or PPH storage tanks EXTRUSION COILING

Tanks manufactured by extrusion winding offer good value for money and are ideal for applications involving corrosive chemicals, heavy products or heavy loads, or for applications requiring large tank quantities.

The advantages of an extrusion-wound tank:

Affordable side

Resistance to corrosive products

Impact resistance

Lightweight and easy to transport

- Affordable cost: This process is relatively inexpensive, enabling mass production of tanks at a reasonable cost.

- Corrosion resistance: Tanks manufactured by extrusion winding can be made from corrosion-resistant materials such as polyethylene and polypropylene, making them ideal for applications involving corrosive chemicals.

- Impact resistance: Tanks manufactured by extrusion winding are generally more impact-resistant than steel or fiberglass tanks, making them ideal for applications involving heavy products or heavy loads.

- Lightweight: Tanks manufactured by extrusion winding are generally lighter than steel or fiberglass tanks, making them easier to handle and install.

- Single skin

Single-wall tanks are cylindrical containers used for storing liquids and gases. They are often used in industrial and commercial applications to store chemicals, water, fuel, food and industrial liquids. In this article, we’ll explore the advantages and disadvantages of single-wall tanks, as well as the different materials used to make them.

Building materials

Single-wall tanks are made from stainless steel, polyethylene-coated steel or plastic materials such as high-density polyethylene (HDPE) or polypropylene (PP). Stainless steel is corrosion-resistant and can be used to store less aggressive chemicals, while HDPE and PP are lightweight and easy to handle. Polyethylene-coated steel combines the advantages of other materials, with excellent corrosion resistance and long service life.

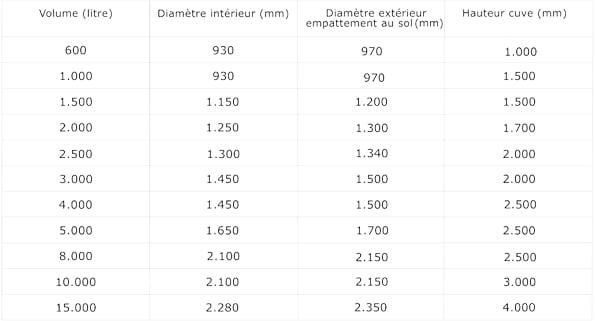

Storage capacity

Single-wall tanks can be manufactured in a variety of sizes to suit your storage needs, from small tanks of just a few liters to tanks of tens of thousands of liters. This means you can select a tank to suit the quantity of liquid you wish to store.

Benefits

Single-wall tanks are inexpensive, easy to install and maintain. They also offer excellent resistance to corrosion and chemicals, making them ideal for industrial and commercial applications. What’s more, their simple design makes them easy to handle and move when required.

- Integrated double skin / double envelope / retention

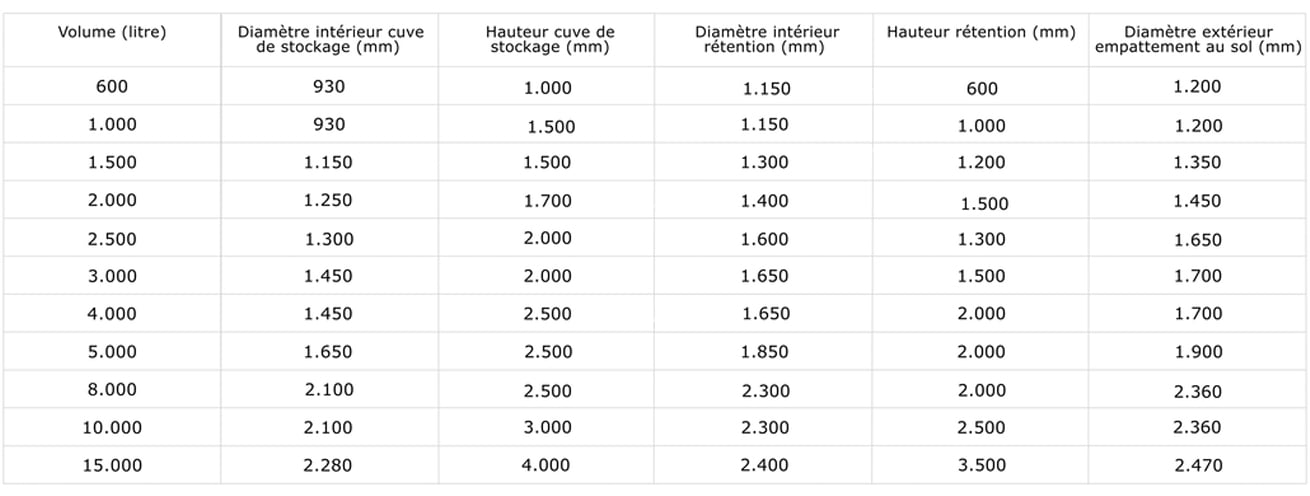

Double-jacketed tanks are the right choice for applications requiring safe, durable storage of chemicals, industrial liquids and hazardous materials. This type of vessel consists of two concentric walls forming an intermediate cavity called the “interspace”.

This empty space provides additional protection against leaks, heat loss, fire and explosion.

What’s more, the double enclosure provides additional safety for people, the environment and property.

Double-jacketed tanks can also be fitted with drain, fill and level devices for convenient maintenance and operation. What’s more, they can be customized to the specific needs of each application, with options such as handling equipment, loading ports and safety accessories.

Double jacketed tanks are versatile and can be used for a wide range of applications, including the storage of chemicals, petroleum products and foodstuffs, as well as water treatment applications.

In conclusion, jacketed tanks are a reliable solution for industrial applications requiring safe, durable storage. With their extra protection against leakage, they guarantee maximum safety for people, the environment and property.

HDPE and PPH storage tanks boilerwork polyfusion plates

HDPE and PPH storage tanks in polyfused sheet metal are reliable, durable and economical storage solutions for a variety of industrial applications. Designed to handle chemicals, liquids, petroleum products and other products, these tanks are made from top-quality materials to ensure long life and optimum performance.

The use of HDPE (high-density polyethylene) and PPH (reinforced polypropylene) for the construction of these tanks offers numerous advantages:

Corrosion resistance

Lightweight

Weather resistance

Affordable side

The use of HDPE (high-density polyethylene) and PPH (reinforced polypropylene) in the construction of these tanks offers numerous advantages. Firstly, these materials are corrosion-resistant, making them suitable for handling aggressive chemicals. What’s more, they’re lightweight and easy to handle, making them an ideal choice for mobile applications and temporary installations.

HDPE and PPH storage tanks made from polyfusion sheet metal are also highly flexible in terms of configuration. They can be designed to meet the specific requirements of each application, with customized sizes and shapes to suit unique storage needs. What’s more, they can be fitted with various accessories, such as taps, valves and level indicators, to enhance functionality and ease of use.

HDPE and PPH tanks with polyfused plate boilerwork are also particularly robust and weather-resistant. They can be used in harsh environments without fear of deformation or corrosion, making them particularly suitable for outdoor use.

- Differences between single and double skin tanks

Single-skin and double-skin tanks are two different types of storage tank. Single-skin tanks are made from a single layer of material, generally HDPE (high-density polyethylene) or PPH (high-temperature polypropylene). They are often used to store products at moderate temperatures and can be an affordable option for storing non-toxic products.

Double-skinned tanks, on the other hand, have an inner layer in HDPE or PPH and an outer layer in the same material. They are designed to provide extra protection for stored products, especially those that are toxic or corrosive. The double jacket also provides better thermal insulation to keep product temperatures stable, which can be important in certain industrial applications.

- Single skin

HDPE and PPH storage tanks with single-skin polyfusion plate boilerwork are reliable, cost-effective storage solutions for industrial and commercial applications. With their simple, robust structure, these tanks are ideal for storing chemicals, liquids and food products. easy to install and move, they are ideal for mobile applications. The use of HDPE and PPH for the manufacture of these tanks

ensures high chemical resistance and long-term durability. The single-skinned polyfused plate reinforces the tank’s solidity, while offering a smooth surface for easy cleaning. They can be placed outdoors without fear of deformation or corrosion, making them a popular choice for outdoor applications.

The use of HDPE and PPH in the manufacture of these tanks ensures high chemical resistance and long-term durability. The single-skinned polyfused plate reinforces the tank’s solidity, while offering a smooth surface for easy cleaning. They can be placed outdoors without fear of deformation or corrosion, making them a popular choice for outdoor applications.

HDPE and PPH storage tanks with single-skin polyfusion plate boilerwork can be manufactured to your specifications, including size, shape and capacity. They can also be fitted with a range of accessories, such as safety valves, taps and pressure gauges, to ensure safe, convenient operation.

- Integrated double skin / double envelope / retention

Compared to single-skin tanks, the storage tanks double-skinned in HDPE and PPH are more reliable and durable, with a enhanced protection against leaks and damage. What’s more, their double layer of protection provides better thermal insulation for maintain the temperature of stored products at a stable level and constant.

When choosing a storage tank, it is important to consider several criteria, such as storage capacity, compatibility with with stored products, construction quality and safety. Double-skinned storage tanks in HDPE and PPH can be customized and configured to suit the specific needs of each customer, guaranteeing optimal and reliable use of the tank.

There are many examples of successful projects that have used double-skinned storage tanks, particularly in the chemical, oil and food industries. Quality and reliability of these tanks is guaranteed by their manufacture in polyfused plate boilermaking, which ensures safe, reliable of the tank.

Our entire team is available to discuss your projects

Contact us now!

- +33(0)4 42 12 51 72

- info@stockage-et-systemes.com

- 625 Av. Georges Vacher Z.I 13790 Rousset

What are you looking for?…suggestions