Boxes, dosing cabinets, transfer, pumping

DOSINGBOX® range

- DOSINGBOX® 1 door for 1 or 2 pumps

- DOSINGBOX® 2 doors for 2 or 3 pumps

- DOSINGBOX® 3 doors up to 5 pumps

PANEL® range, multi-purpose enclosures for small spaces, custom-built metal enclosures

Pumping and dosing are essential in various industrial processes and in water treatment. To guarantee the smooth running of the process and ensure the efficiency and precision of these operations, it is essential to have top-quality equipment.

In industry and many other fields, it is essential to use transfer, pumping and dosing cabinets for transporting, transferring and storing toxic or corrosive chemicals. Indeed, it is highly recommended to ensure the safety of the personnel in charge by investing in appropriate facilities.

The DOSINGBOX® range to facilitate the transfer, pumping and dosing of your chemicals

Whatever the nature of your needs, Stockage & Systèmes has the right solution with the DOSINGBOX® range. Specializing in customized plastic sheet metal work, we can also offer you our range of single- and double-shell storage tanks for all kinds of complex situations. If you choose the DOSINGBOX® range, you can select the one-door model for one or two pumps, the two-door model ideal for two or three pumps, or the three-door version for up to 6 pumps. Discover the PANEL® range of multi-function transfer, pumping and dosing enclosures dedicated to small spaces.

Stockage & Systèmes is the partner you need to equip you wisely. A specialized team is at your disposal for turnkey installation of your transfer, pumping and dosing cabinets. Please do not hesitate to contact our sales department for further information on the solutions that interest you.

The DOSINGBOX®: a compendium of innovations for safe chemical dosing

Designed, manufactured and marketed by Stockage & Systèmes, the DOSINGBOX® integrated dosing box protects operators, secures installations and protects the environment from all the dangers inherent in pump dosing operations.

DOSINGBOX® 1,2,3,4,5 or 6 pump dosing units are designed and sized to accommodate all makes of pump. Regardless of the brand selected, our customers are free to choose whether to supply the pumps themselves or order them from us.

Pumps, valves, pulsation dampeners, measuring jars and other associated equipment make up a functional, rapidly installed assembled product.

Choosing DOSINGBOX® means opting for complete pre-assembled solutions that are ready to use and quickly installed !!

– A single point of contact for a finished solution, ready for hydraulic and electrical connections

– Choose from up to 100 possible standard fixtures + all non-standard ones…

– Adapt to any configuration, without specifications

– Control access to pumps with padlockable doors

– Avoid the risks associated with product and pipe connection errors

– Eliminate splash hazards in the event of leaks or pressurized piping and collect drips

– Equipment supplied with hydraulic test certificates, commissioning manual and technical file

– Description and standard equipment

– Molded HDPE, U.V. resistant and 100% corrosion-proof

– Piping and equipment in PVC, PVDF, HDPE, PPH, stainless steel

– 1 , 2 or 3 doors, large transparent glass openings for easy access to pumps

– PPE box integrated into door + 1 set of PPE supplied (overalls, gloves, goggles)

– Drip tray volume from 25 to 65 liters with drain valve

– PEHD brackets and plates for pumps and process equipment

– Overflow G3/4″ with plug Outlet G 1/2″ with plug

– Ventilation for 100% corrosion-resistant aerators

– Marking standard recommendations engraved in the mass

– Mounting on tank, bracket or wall – Weight 30, 45 or 60kg empty

– Free choice of door colors, engraved personalization

– Fitted with numerous options: leak detector, forced-air heater, strainer, alarm kit, bottom drain, double-jacket connection kit, pressure gauge, etc.

Designed for the chemical, surface treatment, food processing and water treatment markets, for dosing fluids such as :

ferric chloride, soda ash, sodium hypochlorite, calcium nitrate, WAC, alumina sulfate, citric acid, hydrochloric acid, sodium bisulfite, urea, etc…

DOSINGBOX®, tried-and-tested products that will make your dosing systems exemplary in terms of safety and environmental protection.

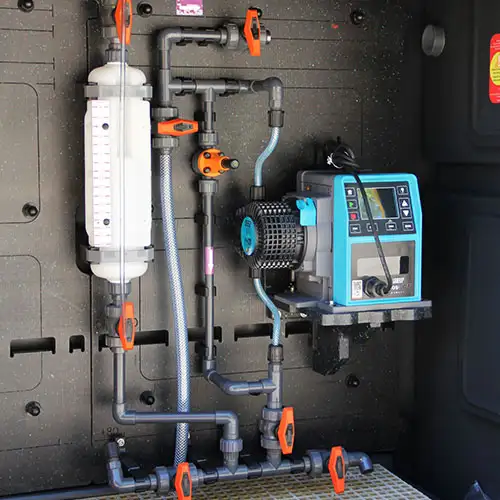

DOSINGBOX® 1 Door

- Description:

- – 1 padlockable door

- – Transparent glass

- – Door-mounted PPE box

- – 1 set of PPE

- – Recovery volume 25 liters

- – PVC DN20 cabinet drain valve

- – 1 set of plates + HDPE brackets for pumps and equipment

- – Overflow spigot

- – Leak detector tapping

- – Marking standard recommendations

- – Mounting on tank, bracket or wall

- – Standard grey/yellow

- – Weight 30kg empty

- Options :

- – Strainer at cabinet inlet

- – Pressure gauge on diaphragm separator (pump discharge pressure pressure control)

- – Horizontal float type leak detector, NO or NC, breaking capacity 250V/1A/50W/0VA

- – Convection heater 400-475W / 230VAC (for risk of frost)

- – 3-function ALARM kit (RED flashing light, GREEN flashing light, siren electronic siren) to provide information on pump malfunctions or the presence of liquid in the retention tank

- – Inflating kit for anti-pulse balloon (supplied in plastic case)

- – Bottom drain for complete emptying of the cabinet, with DN20 PVC valve

- – Versatile 2” Gas double-jacket connection kit

- – Electrical junction box

- – Customer logo engraving

- – Colors other than grey/yellow

- – Frame for floor mounting

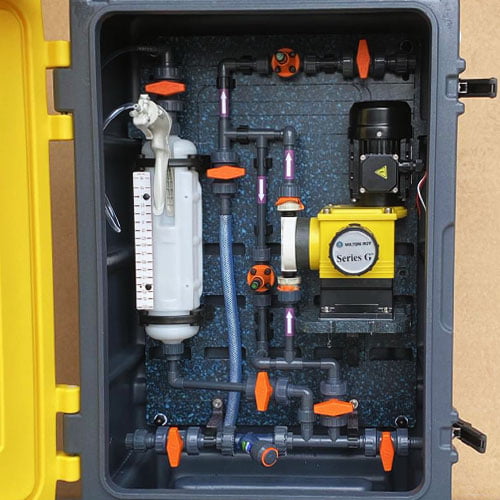

DOSINGBOX® 2 Doors

- Description:

- – 2 padlockable doors

- – Transparent glass

- – Door-mounted PPE box

- – 1 set of PPE

- – Drip tray 45l

- – PVC DN20 cabinet drain valve

- – 1 set of turntables

- – Ergonomic PEHD brackets for pumps and processes

- – Overflow spigot

- – Leak detector tapping

- – Marking standard recommendations

- – Double mounting on tank, bracket or wall

- – Standard color: gray/yellow.

- – Weight 45 kg empty

- Options :

- – Strainer at cabinet inlet

- – Pressure gauge on diaphragm separator (pump discharge pressure pressure control)

- – Horizontal float type leak detector, NO or NC, breaking capacity 250V/1A/50W/0VA

- – Convection heater 400-475W / 230VAC (for risk of frost)

- – 3-function ALARM kit (RED flashing light, GREEN flashing light, siren electronic siren) to provide information on pump malfunctions or the presence of liquid in the retention tank

- – Inflating kit for anti-pulse balloon (supplied in plastic case)

- – Bottom drain for complete emptying of the cabinet, with DN20 PVC valve

- – Versatile 2” Gas double-jacket connection kit

- – Electrical junction box

- – Customer logo engraving

- – Colors other than gray/yellow

- – Frame for floor mounting

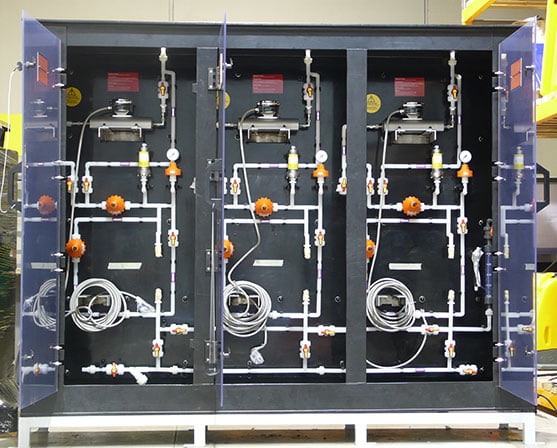

DOSINGBOX® 3 Doors

Description

- – 3 padlockable doors

- – Transparent glass

- – Door-mounted PPE box

- – 1 set of PPE

- – Drip tray 65l

- – PVC DN20 cabinet drain valve

- – PEHD brackets for pumps and process equipment

- – Overflow spigot

- – Leak detector tapping

- – Marking standard recommendations

- – Triple mounting on tank, stand or wall

- – Standard color: gray/yellow.

- – Weight 60 kg empty

Options :

– Product label (product, hazard pictogram)

– Strainer at cabinet inlet

– Pressure gauge on diaphragm separator (pump discharge pressure pressure control)

– Horizontal float type leak detector, NO or NC, breaking capacity 250V/1A/50W/0VA

– Convection heater 400-475W / 230VAC (for risk of frost)

– 3-function ALARM kit (RED flashing light, GREEN flashing light, siren electronic siren) to provide information on pump malfunctions or the presence of liquid in the retention tank

– Inflating kit for anti-pulse balloon (supplied in plastic case)

– Bottom drain for complete emptying of the cabinet, with DN20 PVC valve

– Versatile 2” Gas double-jacket connection kit

– Electrical junction box

– Customer logo engraving

– Colors other than gray/yellow

– Frame for floor mounting

Technical sheet

Download our document to see product specific data.

PANEL® range

Panels, or multi-purpose enclosures, are versatile pieces of equipment that lend themselves to an unlimited variety of applications. They offer reliable protection for pumps, valve boxes and flowmeters, as well as for water analysis, chlorination, dosing, chlorine dioxide installation, swimming pools, pH control and small container storage.

Panel options include a choice of cabinet and/or door colors, the possibility of incorporating a logo in the mass, an HDPE plate for process equipment, a pump support bracket, a shelf, a DN15 PVC valve for draining, an identification plate, a leak detector and an overflow.

These multifunction boxes are designed to meet the most varied requirements of professionals. They combine strength, quality and practicality to provide optimum protection for your equipment.

Bespoke boiler boxes

Are you looking for a tailor-made solution to protect and organize your critical equipment?

Custom-built enclosures are the ideal solution for your specific needs.

Manufactured to your dimensions and requirements, these enclosures offer optimum protection against the elements, while providing easy access to your equipment.

Whether for pump protection, water analysis, chlorination, dosing, chlorine dioxide installation or small container storage, custom-built boiler enclosures are designed to fit your unique needs.

Transfer, pumping and dosing of chemicals: more efficient solutions

The mixing or dissolving of liquid, viscous or gelled chemicals, etc., requires the utmost precision to avoid accidents. Specialized technicians have developed high-precision pumping equipment and adapted materials that enable systematic process automation. The pumping and dosing equipment available on the market is increasingly efficient. Whatever your requirements, you can easily find transfer, pumping and dosing enclosures and cabinets.

1- Why do you need specific equipment?

Transfer, pumping and dosing solutions are essential for accurate product transfer. In fact, when this dose is high, it can lead to major property damage, personal injury or ecological disasters. For example, if too much acid is poured into a tank or neutralization basin, the risk of temperature rise can lead to material degradation or toxic fumes.

The financial losses that may result from incidents that may arise due to dosing or pumping problems during a transfer will be far more expensive than the purchase of suitable equipment such as transfer, pumping and dosing cabinets, fitted with the necessary sensors. In warehouses, a single handling error resulting in a leak of liquid or vapors can compromise the health and safety of operators. The dosing process is therefore an essential point that must not be overlooked.

2- Precise and efficient transfer, pumping and dosing boxes and cabinets

Containers dedicated to these types of products are equipped with dosing pumps to facilitate the work of your teams. When the conditions of use are meticulously respected, you are safe from all forms of risk.

There are many different types of metering pump, which is why the expertise of qualified professionals is essential for the design and installation of central and buffer chemical storage facilities. The installer must take into account the “flow-pressure” torque, the type of products to be transferred and dosed, the temperature of the fluid and its compatibility with the surrounding chemical elements. He must also consider the materials used in the pumps, which will be in contact with the pumped liquids, in order to design transfer, pumping and dosing cabinets.

Solutions resulting from many years of experience in transfer, pumping, dosing, control

It’s important to understand that dosing errors are not the only source of accidents. Indeed, the immediate environment can expose operators to hazards: extreme temperatures, corrosive environments, explosive environments, etc. To protect them from accidents, careful preparation is essential. Systems of regulation or subordination must be introduced, taking into account the specific parameters of each location.

Site security is therefore an aspect that must not be neglected. Benefit from personalized support and expert advice for the installation of your storage equipment. Our team’s expertise will enable you to anticipate risks and protect your staff in charge of chemical pump dosing operations. Stockage & Systèmes can take care of the turnkey installation of your equipment: we can provide you with transfer, pumping and dosing cabinets that perfectly meet your needs.

We take care of all the design and manufacturing stages of the equipment we offer, to guarantee reliability and ease of use. HDPE polyethylene transfer, pumping and metering boxes and cabinets are distinguished by their durability (at least 25 years), light weight and high resistance to the effects of chemicals. What’s more, this material is perfectly recyclable and meets today’s environmental criteria. Easy to adjust, this equipment considerably simplifies the dosing of the products it contains. We recommend equipment that is resistant to corrosion, UV rays, impact, etc. The materials used are always compatible with the liquids they are likely to contain.

Our entire team is available to discuss your projects

Contact us now!

- +33(0)4 42 12 51 72

- info@stockage-et-systemes.com

- 625 Av. Georges Vacher Z.I 13790 Rousset

What are you looking for?…suggestions